Cardboard Tube Manufacturers

Cardboard tubes, cylindrical structures made of paperboard, play a crucial role in various industries due to their versatility and durability. These tubes find applications in packaging, construction, arts and crafts, and more. They provide a practical and eco-friendly solution for a wide range of needs. Read More…

Ace Paper Tube Corporation open_in_new

Location: Cleveland, OH

As a member of the Member of the Independent Converters Association, we know our business and the business of cardboard tubes. Our tubes are some of the strongest in the industry and we can meet a huge variety of needs from many different industries. We specialize in shipping tubes and we always place customer needs as our number one priority. Contact us today to find out how we can serve you!

Valk Industries, Inc. open_in_new

Location: Greeneville, TN

Valk Industries provides engineering and manufacturing services for cardboard tubes as well as custom thermoformed items like clamshells, blister packs, trays and filler material. Operations began in 1975, and Valk has expanded from providing custom machining and fabrication processes to over wrapping, component assembly and packaging products. Call us today!

Western Container Corp. open_in_new

Location: Beloit, WI

Western Container partners with the world`s top spiral tube equipment designers & paperboard manufacturers, to bring our customers the very best paper tubing and precision cores. We can custom design your cores and specialty tubes with one color in-line printing, two color off-line printing & four color process labeling. Our large inventory allows for fast shipping. We’re “wound-up” to...

Chicago Mailing Tube open_in_new

Location: Chicago, IL

Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical. CMT has been meeting custom size and design requirements for its customers since 1902. We make our products from quality recycled materials that are fully recyclable. We assure you that your order will be shipped on time and delivered right.

Paper Tubes & Sales open_in_new

Location: Dallas, TX

We are Paper Tubes & Sales, a family-owned and operated business since 1975 and one of the largest independent manufacturers of paper tubes, composite cans, and paper cores in the United States. We take pride in maintaining personal relationships with our customers while also having a nationwide presence with our fleet of trucks. Our company has grown through hard work and outstanding...

Wes-Pac Converting open_in_new

Location: Belvidere, IL

We are Wes-Pac Converting, a family-owned custom packaging manufacturing company specializing in custom tubes and cores. With over 30 years of experience, we have established ourselves as a trusted source for high-quality packaging products and services. Our team of experts is dedicated to providing innovative and customized solutions that meet our clients' specific needs.

At Wes-Pac...

More Cardboard Tube Manufacturers

Cardboard tubes, made from durable paperboard, are essential in numerous industries for their versatility and strength. They are widely used in packaging, construction, and arts and crafts, offering a practical, eco-friendly solution for various applications.

Creation of Cardboard Tubes

The creation of cardboard tubes involves key steps to achieve their cylindrical shape. First, the paperboard is cut into strips of the desired width and thickness. These strips are coated with adhesive for bonding strength, and then either a spiral or convolute wound is used to form the tubes.

Spiral Winding

In the spiral winding method, adhesive-coated paperboard strips are tightly wound around a mandrel, layering in a spiral pattern with slight overlaps. This technique produces seamless, strong, and rigid tubes. Spiral wound cardboard tubes are often used for postal mailing, providing secure packaging and protection for documents, blueprints, and posters during shipping.

Convolute Winding

In convolute winding, operators wrap adhesive-coated paperboard strips around a mandrel at a predetermined helical angle. This method produces spirally wound tubes with gaps between the wraps, resulting in a textured surface. Manufacturers commonly employ convolute winding to create cores for paper towels, tissue rolls, and other rolled materials, enhancing grip and facilitating easy dispensing. These cardboard tubes are engineered to provide strength, stability, and efficient use of rolled materials.

Both spiral winding and convolute winding methods efficiently produce cardboard tubes with specific characteristics and applications. Manufacturers choose the winding method based on intended use, desired strength, and surface texture requirements. These processes enhance the versatility and customization options of cardboard tubes, allowing them to meet diverse industry needs.

Cardboard Tube Components

Cardboard tubes are composed of essential components that collectively ensure structural integrity, strength, and functionality. These components typically include an outer layer, an inner layer, and adhesive. The outer layer, usually crafted from durable paperboard or cardboard, offers protection and durability, safeguarding contents from external impacts and maintaining the tube’s shape. The inner layer, also constructed from paperboard, enhances structural strength and stability, reinforcing the tubes to prevent collapse or deformation under pressure. The adhesive is applied between these layers to securely bond them, ensuring the tube remains intact and resilient.

While these components are foundational, variations occur based on specific applications. For example, some cardboard tubes may include additional reinforcement layers, such as high-strength materials like fiberglass or plastic, to bolster structural integrity. This makes them suitable for rigorous applications such as concrete forming. Moreover, certain tubes may incorporate waterproof or moisture-resistant coatings, protecting against moisture and humidity. Such features are advantageous for applications like outdoor display or shipping of posters.

The integration of these components and variations enables cardboard tubes to be customized to meet precise specifications across different industries. Manufacturers can adapt composition and design to produce tubes that deliver essential strength, protection, and specialized features required for a wide range of applications.

Limitations of Cardboard Tubes

While cardboard tubes offer numerous advantages, they are subject to certain limitations. Design constraints may arise from size restrictions or difficulties in achieving intricate shapes. Usage limitations include weight restrictions and susceptibility to temperature variations. Additionally, certain applications may demand specialized properties, such as chemical resistance or suitability for extreme environmental conditions, which standard cardboard tubes may not inherently possess.

Overcoming Limitations

Manufacturers are actively overcoming cardboard tube limitations through continuous innovation. Advancements in design techniques leverage modern technology and engineering expertise to create complex shapes and structures that were once challenging. This innovation expands possibilities for customized applications. Enhanced material selection, such as different paperboard types, additives, and reinforcements like fiberglass or plastic, strengthens tubes to withstand demanding environments or meet specific performance needs.

Specialized coatings have significantly broadened the capabilities of cardboard tubes. Waterproof and moisture-resistant coatings protect against moisture damage, ensuring structural integrity in wet or humid environments. Fire-resistant and chemical-resistant coatings extend applications to industries requiring safety and corrosion resistance. These innovations push the boundaries of cardboard tube technology, enhancing versatility and performance across diverse industries and applications.

Benefits of Cardboard Tubes

Cardboard tubes are prized across industries for their multitude of advantages, chief among them their eco-friendly composition. Crafted from renewable and recyclable materials, these tubes offer a sustainable packaging alternative compared to plastic or metal counterparts. Their easy recyclability not only minimizes waste but also reduces environmental impact.

Beyond their environmental benefits, cardboard tubes boast exceptional versatility. They can be tailored in size, length, diameter, and strength to precisely fit diverse specifications. This adaptability allows manufacturers to meet the unique demands of various sectors and applications effectively. Moreover, cardboard tubes can be effortlessly customized with branding, labels, or prints, making them a powerful asset for product packaging and marketing strategies.

Cardboard tubes offer cost-effective transportation and shipping benefits due to their lightweight construction. They reduce shipping costs and enhance handling efficiency. They are also economical compared to alternative packaging materials, making them a preferred choice for businesses.

Additionally, cardboard tubes provide robust protection by maintaining the integrity of enclosed items, and shielding against bending, crushing, or impact during transit. Their sturdy design minimizes damage and reduces reliance on extra protective materials. Cardboard tubes offer effective thermal insulation, safeguarding temperature-sensitive items from extreme conditions during transportation or storage.

In summary, cardboard tubes are valued for their eco-friendliness, versatility, lightweight design, cost-effectiveness, superior protection, branding potential, and thermal insulation capabilities. These attributes make them highly desirable across various industries and applications.

Applications of Cardboard Tubes

Cardboard tubes are highly versatile and durable, finding extensive use across various industries. In packaging and shipping, they safeguard posters, documents, blueprints, and delicate items from bending or creasing due to their rigid structure. In construction, they serve as reliable concrete formwork, providing temporary molds for columns and pillars withstanding poured concrete pressures.

Additionally, cardboard tubes play a pivotal role in arts, crafts, and DIY projects. Their cylindrical shape enables creative and unique designs, making them a favored material for prototypes, models, artwork, and even musical instruments.

In industrial and commercial environments, cardboard tubes serve as essential cores for various materials. They are utilized to wind textiles, films, papers, and other rolled materials into convenient, easily dispensable rolls. These versatile rolls are integral to industries including textiles, printing, and packaging.

Additionally, cardboard tubes find applications in agriculture, where they function as plant protectors and tree shelters. They offer vital support and shielding for young plants, safeguarding them against adverse weather and wildlife impact.

Cardboard tubes are versatile across industries like retail, serving as point-of-sale displays, countertop stands, and innovative packaging solutions. They offer eco-friendly options for product display and branding opportunities.

Their adaptability and structural strength make cardboard tubes indispensable across diverse sectors, including packaging, construction, arts, and industry, highlighting their customizable features and eco-friendly credentials.

Choosing the Most Appropriate Cardboard Tube

Choosing the most suitable cardboard tube for a specific application involves evaluating several factors to ensure optimal performance and functionality. Key considerations include tailoring the size and dimensions of the tube, such as diameter and length, to accommodate the intended use and the size of items to be stored or transported. It’s crucial to select dimensions that provide a secure fit without excess space, minimizing the risk of movement or damage.

Additionally, the strength and durability of the cardboard tube play a critical role. Factors like the thickness of the paperboard and the construction technique affect the tube’s load-bearing capacity and its ability to withstand external forces. Choosing a tube with adequate strength is essential to meet the weight and handling requirements of the application.

Moreover, addressing specific application needs is vital. For instance, if the contents are sensitive to moisture, choosing a waterproof or moisture-resistant tube may be necessary. Similarly, environments with extreme temperatures or corrosive substances demand tubes with appropriate coatings or materials for protection.

Considerations for specific application requirements are crucial when selecting cardboard tubes. For instance, if the contents are sensitive to moisture, opting for a waterproof or moisture-resistant tube is essential. Similarly, tubes exposed to extreme temperatures or corrosive substances should be chosen with appropriate coatings or materials.

Consulting manufacturers or suppliers is recommended for expert guidance on selecting the right cardboard tube size, strength, and specifications. They can provide valuable insights based on their industry experience. Requesting samples and conducting tests can further help evaluate tube performance under specific conditions, ensuring they meet desired criteria.

By carefully assessing size, strength, and specific needs, and seeking professional advice when necessary, individuals and businesses can confidently choose the most suitable cardboard tube for their application. This ensures the tube will offer necessary protection, functionality, and durability as required.

Choosing the Proper Cardboard Tube Supplier

For optimal results when sourcing cardboard tubes from suppliers, utilize our directory featuring detailed profiles of various suppliers. Each profile outlines their expertise and capabilities, offering a direct contact form for inquiries or quotes. Utilize our patented website previewer to swiftly gauge each supplier’s specialization. Streamline your communication by submitting a single RFQ form to multiple suppliers simultaneously.

Check out our Plastic Bags website

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

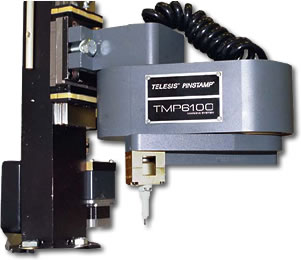

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services