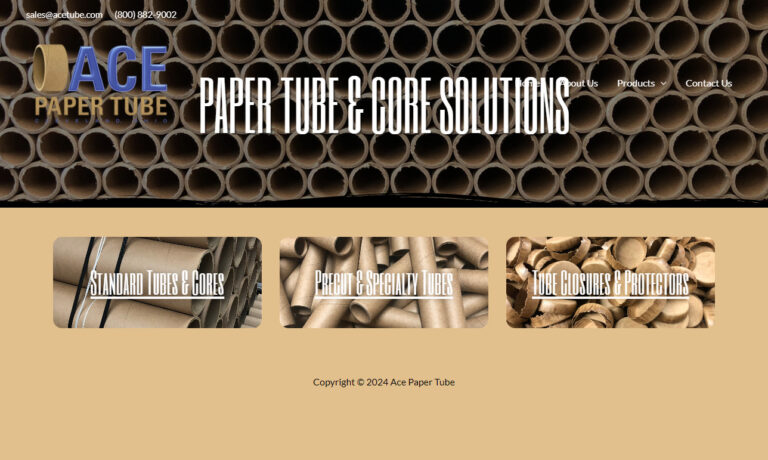

A Composite Can is a cylindrical container that usually has a body made of several layers of paper and the bases or ends made of metal or plastic. A Composite Can is also sometimes called a Combi container, and can often serve a similar purpose as a poster tube. Composite cans are composed of a body, a bottom closure, and a top closure. Read More…

Ace Paper Tube Corporation open_in_new

Location: Cleveland, OH

As a member of the Member of the Independent Converters Association, we know our business and the business of cardboard tubes.

Valk Industries, Inc. open_in_new

Location: Greeneville, TN

Valk Industries provides engineering and manufacturing services for cardboard tubes as well as custom thermoformed items like clamshells, blister packs, trays and filler material.

Western Container Corp. open_in_new

Location: Beloit, WI

Western Container partners with the world`s top spiral tube equipment designers & paperboard manufacturers, to bring our customers the very best paper tubing and precision cores.

Chicago Mailing Tube open_in_new

Location: Chicago, IL

Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical.

Paper Tubes & Sales open_in_new

Location: Dallas, TX

Here at Paper Tubes and Sales we are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams are available to assist you with determining the best paper tube for your application.

Wes-Pac Converting open_in_new

Location: Belvidere, IL

At Wes-Pac Converting, we have made it our mission to ensure that our customers are having their needs and expectations met, and to turn first time customers into lifelong connections. We offer white tubes, kraft tubes, Snap-Loc tubes, telescopic tubes, and more. All of our tubes are 100% recyclable. For more information on how we may be of service, get in touch with our customer service...

More Composite Can Manufacturers

There are four main structures in the body of a Composite Can: the aluminum inner web, multipole intermediate webs, and the label web, and the membrane. The membrane and tear off tabs are made of metals (usually aluminum). The membrane is manufactured in a blanking and deep drawing device. This same device cuts circular slits to make the tear-off membrane. Another machine then manufactures and seals the tear-off membranes. The membrane band is taken from the material reel, blanked, deep drawn and formed.

Closures for Composite Cans come in different forms including aluminum-membranes with tear tab, paper membranes with or without aluminum coating, paper board ends, and paper board shakers among others. These closures can be made from aluminum foil, paper, paper with or without coating. Other closure options are available depending on the company and request of the customer. There are two main kinds of Composite Cans: Spiral Wound Cans & Linear Draw Cans. Spiral Wound Cans are made by diagonally winding and gluing four layers of material together. The bottom layer is usually tin or foil, the two middle layers are usually paper board, and they serve to give the can its structure.

The outermost layer is sometimes optional depending on if the customer will like a label added to the can itself-this typically increases the cost of production. Linear Draw cans are made by drawing the materials through the gluing process and then through the tooling process. After the tube is made, it is the cut into separate cans. These kinds of cans are made in one single process.Composite Cans can be used mainly for packaging everyday household items like coffee whiteners, diet drinks, bread crumbs, hot chocolate mixes, nuts, cakes, spices, tea, cleaning gels and baking sodas among others. Composite Cans offer several advantages such as cost-effectiveness, environmental safety (composite cans are mostly made from recycled products), durability, versatility and user friendliness in general.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

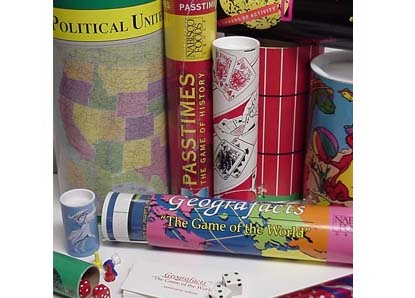

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services